ODME (Oil Discharge Monitoring Equipment)

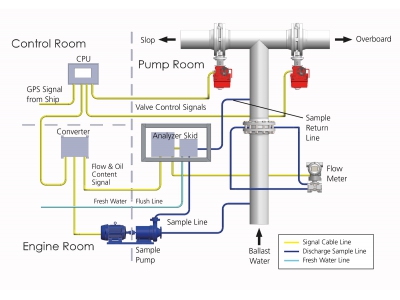

The ODME principle is based on a measurement of oil content in the ballast water, which is held up against the regulations and requirements.

By data interpretation an automated process either allows or prevents discharge of ballast water.

A sample point on the discharge line allows the analyzer to determine the oil content of the ballast water in PPM.

The analyzer is self-maintaining by periodical cleansings with fresh water, and therefore requires a minimum of active maintenance from the crew.

The results of the analyzer are sent to a computer, which determines whether the oil content values are to result in overboard discharge or not.

The valves that direct the ballast water either over board or to slop tank are of course controlled by the Integrated computer, and a GPS signal further automates the process by including special areas and completes the required input for the Oil Record Book.

Because it is required by regulations developed by IMO’s MEPC and adopted by most countries.

By data interpretation an automated process either allows or prevents discharge of ballast water.

A sample point on the discharge line allows the analyzer to determine the oil content of the ballast water in PPM.

The analyzer is self-maintaining by periodical cleansings with fresh water, and therefore requires a minimum of active maintenance from the crew.

The results of the analyzer are sent to a computer, which determines whether the oil content values are to result in overboard discharge or not.

The valves that direct the ballast water either over board or to slop tank are of course controlled by the Integrated computer, and a GPS signal further automates the process by including special areas and completes the required input for the Oil Record Book.

Because it is required by regulations developed by IMO’s MEPC and adopted by most countries.

The regulations have been developed and implemented as a result of some of the worst shipping wrecks during the 70’s causing heavy oil spills and contamination of the maritime environment. As the technology has devolved so have the regulations. Starting with a purely mechanical requirement and manual logging, it now stipulates automated monitoring of oil content, control and logging of speed and data. For instance, all ODME systems installed after January 1st 2005 must utilize ships speed and position in the logging and all hardware and spare parts that are recommended by the manufacturer, should be carried onboard.

The latest amendment to the regulations concerns bio fuel. By January 1st 2016, ships carrying bio fuel must have ODME systems certified to handle just this, as the oil content meter must be able to handle these substances.

But why do I need ODME?

But why do I need ODME?

- ODME obligatory installation MARPOL 73/78 Annex 1, regulation 15

- Ships real time position inclusion mandatory for ODME installed after 2005 Resolution MEPC.108(49)

- Manufacturer recommended spares should be carried to ensure operation Resolution MEPC.240(65)

- By January 1st 2016, ODME must be certified for Bio fuels in order for vessel to carry them Resolution MEPC.240(65)

- 30 liters of oil per nautical mile

- An accumulated volume exceeding 1/30,000 of the total volume of previous journey’s cargo

Swift Marine Tech Services can offer you:

- RETROFIT

This service is required when the existing ODME needs to be renewed or replaced. We are providing reputable and reliable ODME makers to ensure satisfactory operation and maintenance of your systems. - ANNUAL INSPECTION & CALIBRATION

Annual inspection is required to avoid unnecessary failures (Aiarms). During our annual inspection the ODME System is fully checked and calibrated and tested adjusting, if necessary, according to maker’s instructions. After each inspection the crew is instructed on how to maintain a good working ODME System.